A high master data quality is relevant for many business processes, since numerous departments within the company access the master data. Outdated and poorly maintained data is often the cause of inefficient workflows and leads to delays in business processes. SAP Master Data Governance (MDG) simplifies master data maintenance with predefined processes and automated rules.

Is your master data complete, structured and up-to-date?

Efficient and consistent

Working with SAP MDG brings several advantages: The web interface ensures convenient operation. The user can create and maintain master data in a single tool. Gone are the days when searching for existing material masters in the ERP system was necessary and switching between systems was not only time-consuming but also error-prone. What's more, everyone involved in SAP MDG only sees the fields and information that they really need for their work. Notifications are also transmitted within SAP MDG, supplemented by automatically sent e-mails that inform the user, for example, that there is a task for him to complete within the workflow.

Using default settings, rules and validations

Furthermore, SAP MDG offers the possibility of working with default settings, thereby reducing the required entries to a minimum. This provides the user with an important orientation when maintaining master data. The functionality proves to be particularly helpful if the creation of a new material master is decentralized, so that many potential users are involved who only work on the system occasionally. As a result, they do not always know all dependencies, which increases the risk of errors. Suitable rules can be mapped automatically and support users in maintaining them. Validations check whether the information entered is consistent and complete.

After the requester has submitted a request to create the material, a defined workflow is started so that the request passes through the departments involved one after the other in a defined sequence. SAP MDG also solves the problem of missing feedback from colleagues. The current status of the request can be viewed at any time. This means that the applicant can always see how far the process has progressed.

Workflow using the example of material master data

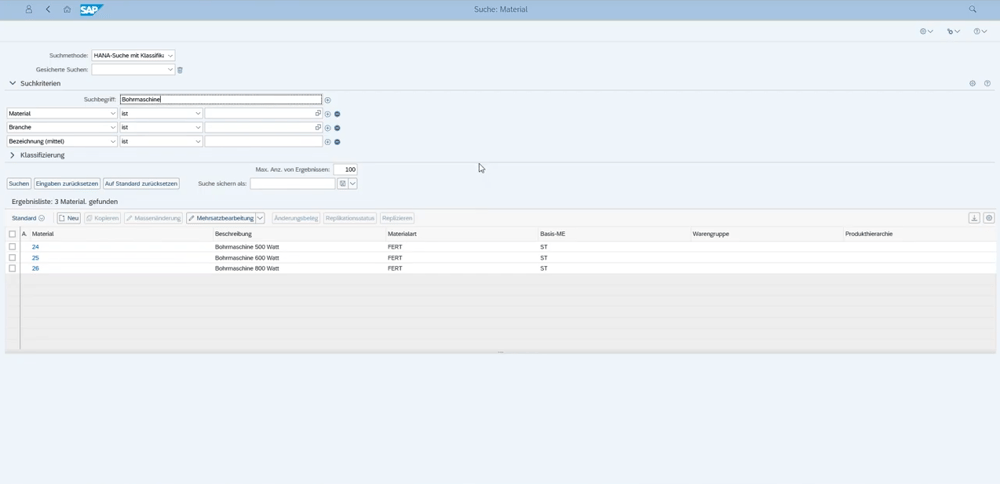

The workflow with SAP MDG is illustrated using the material master as an example. The user first uses the search function to check whether the material already exists in the master data. If this is not the case, the user must request that the material be created. Depending on the type of material, such as raw material, finished material or trading goods, different departments are involved in the following workflow. The process finally ends with the activation of the data record. The requester then receives a message that the material was created successfully.

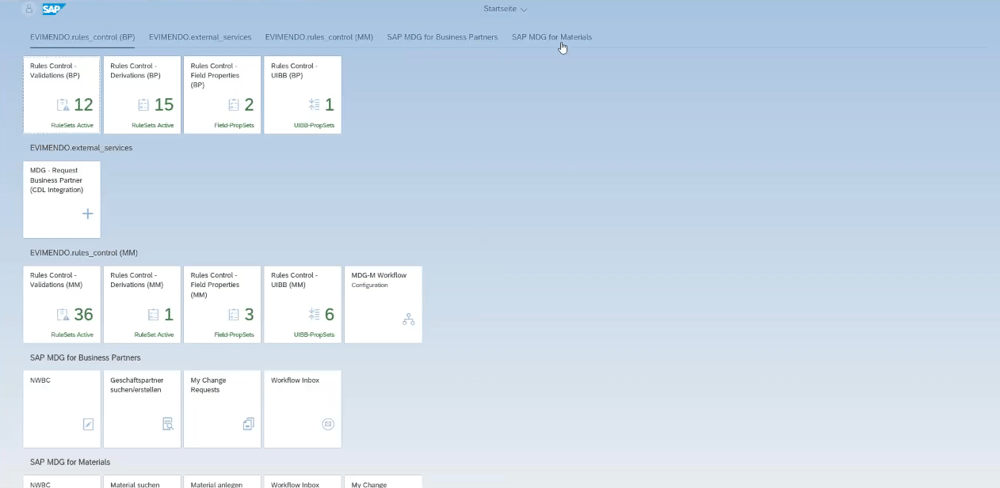

From the Fiori Launchpad, all participants can access their respective tasks in the workflow.

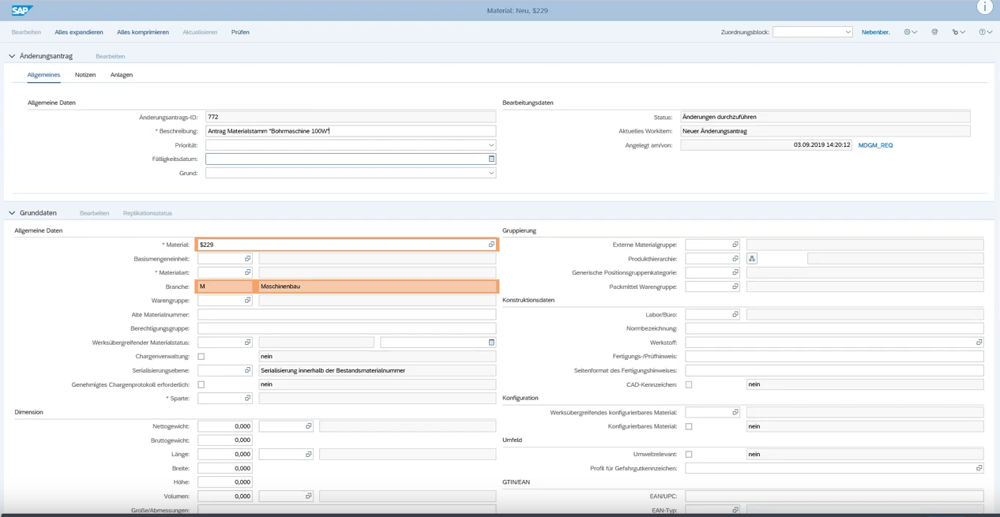

The central entry point in SAP MDG is the Fiori Launchpad. Behind each tile is a different application. One of them relates to searching for and creating material master data. The search is web-based. If a company uses SAP S/4HANA as its ERP system, a keyword search with free text can also be used as a functionality of the HANA database. If the search was unsuccessful, a new material master can be requested directly from the search mask − by clicking on the “New” button. The interface consists of several areas. In the workflow header, the requester finds the change request ID and the description of the material. He can attach documents such as design drawings and note relevant information for the other process participants in the note field. To avoid input errors, the system can, for example, preset the field “Industry”.

First, the user runs the search function to check whether the material already exists.

Depending on the material type, the system uses rules to preassign values during request processing. Using the “Check” field, the system validates certain entries and issues errors and warnings. The requester can only send the request once he or she has filled out all mandatory fields. Later on, the requester can track the status of the request. The requester can no longer make changes, however, and the “Edit” button is hidden.

When you create a new material master, some basic data is requested.

Role determines what is to be seen

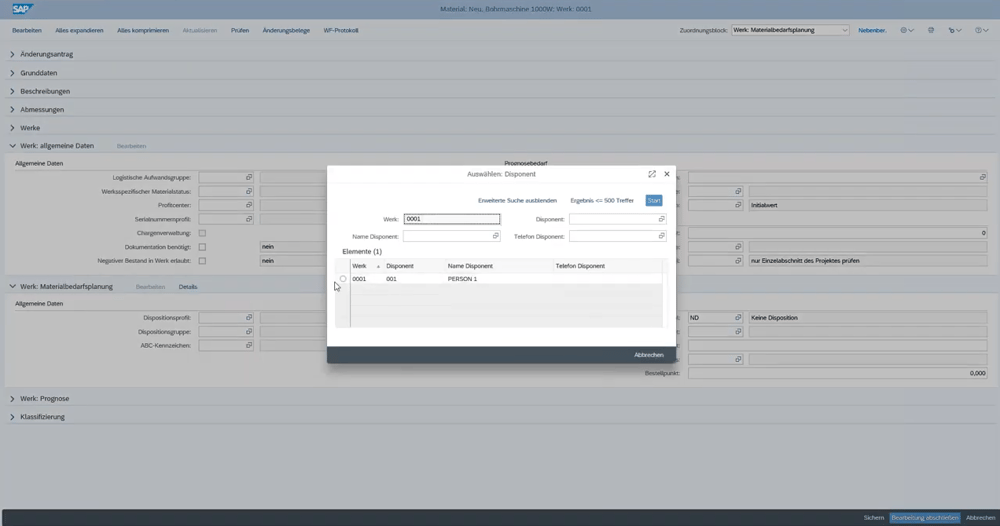

The next workflow step is the maintenance of the plant data. Here, too, the responsible agent only sees certain tiles in the Fiori Launchpad according to his or her role. The workflow inbox contains an overview of the requests to be processed. The user is also shown that a task exists for him or her. Since other entries are relevant in this process step, the processor also sees other fields than the requester previously saw. After he has maintained the plant data, he clicks on “Complete processing”. Now the workflow goes on to the sales department.

The selection of the material planner is part of the plant data.

The same game is played for the sales employee: a notification in his workflow inbox and interfaces in SAP MDG that are tailored to his role. The basic data of the request is always visible, and the sales user is also shown the distribution chains and segments that he or she is to fill. This includes, for example, the sales organization assignment, the minimum delivery quantity and the tax classification. The product hierarchy is also defined as a mandatory field.

Finally to the finance department

The sales employee then sends the application to the finance/controlling department. In his or her work area, the finance colleague sees the change request header and the basic data, as well as the valuation areas for which material valuation, standard price, price control, and so on must be specified. Once the finance department has maintained its data, the material is activated and assigned its own material number. The master data can then be distributed to downstream systems (SAP and non-SAP).

![IBacademy_Logo_blau[496] IBacademy_Logo_blau[496]](https://www.ibsolution.com/hs-fs/hubfs/IBacademy_Logo_blau%5B496%5D.jpg?width=200&name=IBacademy_Logo_blau%5B496%5D.jpg)